www.haskel.vn

NHẬP KHẨU VÀ BÁN BƠM HASKEL TẠI VIỆT NAM

Email: info@haskel.vn Điện Thoại:0913 578 498

HASKEL products

worldwide industrial technology

components and high pressure systems

Hose Test Rigs for testing to Automotive, Industrial and Gas industry specifications that include:

They can be supplied with optional features such as:

Typical hoses being tested include:

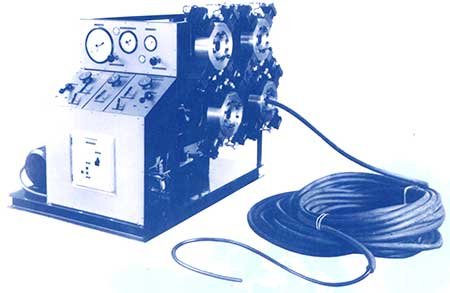

Air leak and decay test rig for power steering hoses in the automotive industry. 7 bar, 3cc/min leak rate

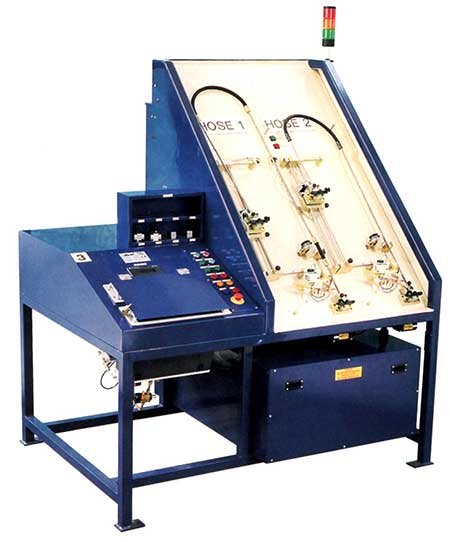

Temperature controlled burst and impulse test rig with environmental chamber. 240 bar, -40°C to +1 25°C

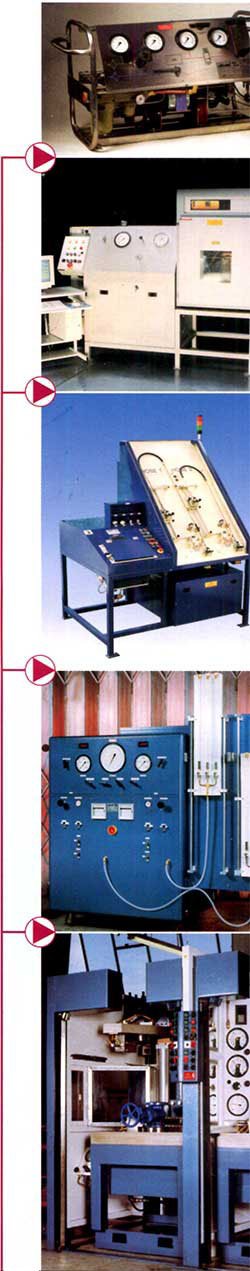

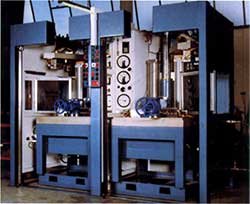

2 station combined hose mandrel extraction and pressure test rig

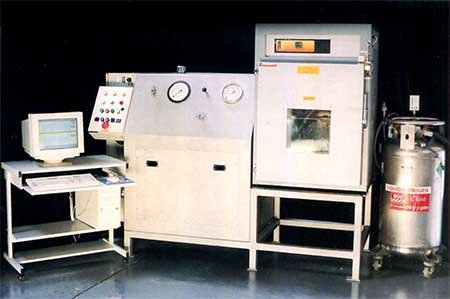

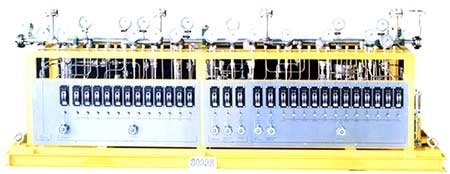

Multiple station hose test rig for hose assembly facilities up to 30,000 psi

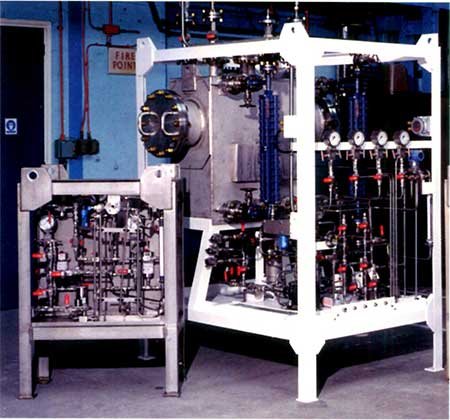

Valve Test Rigs for testing all types of Process Control and Safety Relief Valves to confirm:

Tests include:

Test rigs can be supplied with a range of clamp benches:

Other features:

Relief valve 'pop and flow test rig

Two stations PLC controlled automatic valve test rig for gate valves up to 8" in diameter

Test bench for hydraulic or gas pressure leakage and fi.inctional testing of valves

Pressurized Gas Cylinder and Container Test Rigs for Testing:

Test includes:

Two station air receiver water test rig

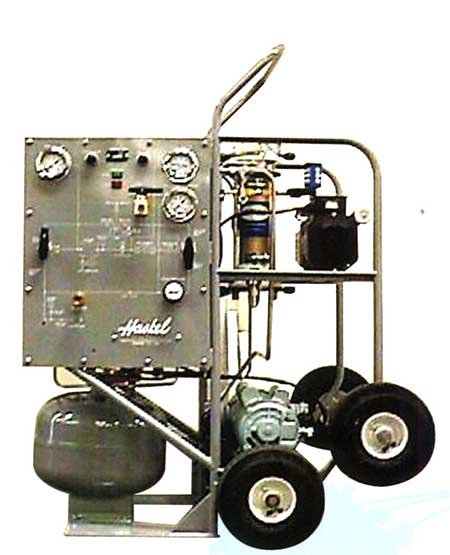

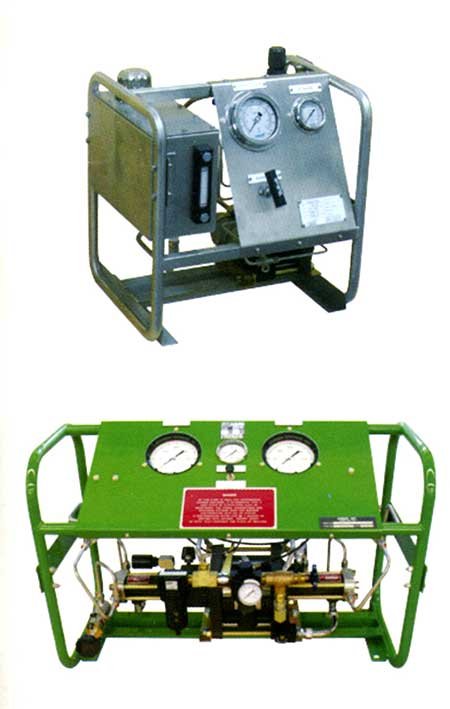

Haskel offers a wide range of small portable test systems, commonly called Testpacs, suitable for a variety of pressure testing applications.

Uses include pressure testing of:

Haskel Testpacs are also commonly used for testing the integrity of hydraulic and pneumatic circuits in the aerospace, mobile and industrial markets.

Gas cylinder stretch test rig complete with moveable burrettes

Testpac 200

Portable hydro-proofer

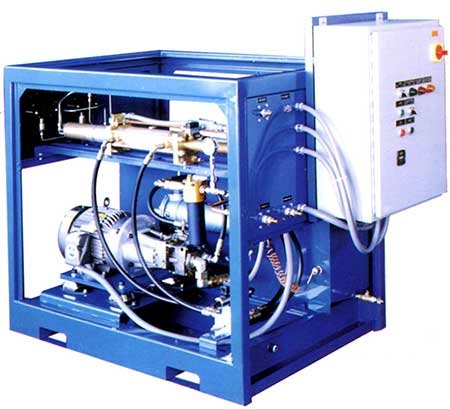

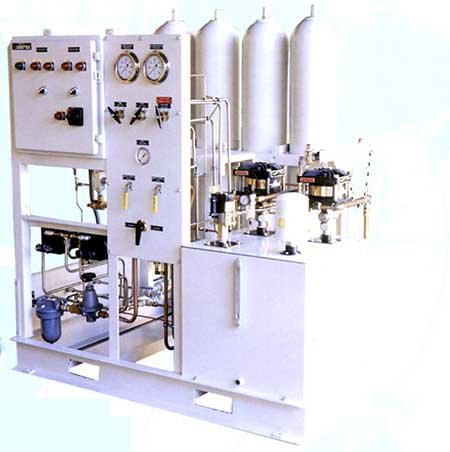

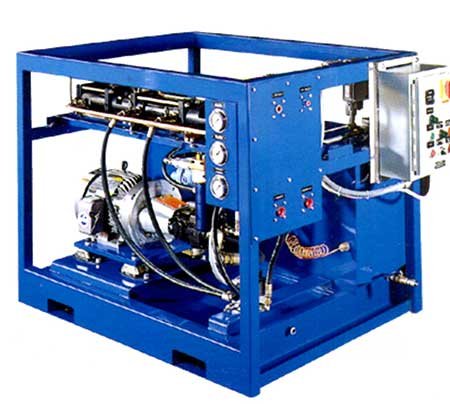

Haskel are specialists in the design, manufacture, test and commissioning of standard and customized systems in a wide range of industries and applications.

Our experience in high pressure gas pressurization and transfer has enabled us to develop our reputation for high pressure gas control technology.

Haskel air and hydraulically driven gas boosters routinely handle the following:

Air service cart - 5500 psig

CNG Refueling Booster System - automotive alternative fuel

Non-magnetic oxygen charging system used in Naval minehunters

Argon charging unit used in defense industry

Hydraulic drive as booster unit - plastic injection molding machine manufacturers

Haskel gas booster systems have also long been employed in a variety of indus-tries where the need for transfer and pressurization of "liquefied" gas exists.

These specialty gases include carbon dioxide, sulfur hexifluoride, freon, halon, propane, ISO-butane and ISO-pentane, to name a few.

Benefits offered by Haskel for these applications include the ability to pump these gases in both their liquid and gaseous states.

SF6 cart for reclaim, recovery & recharge in power generation

Portable liquefied gas transfer unit for halos, etc

Gas charging cart - defense industry

SF6 recovery & recharge handcart

CO2 liquefied gas pumping system -pharmaceutical & biotech industry

Supplying the majority of the world's oil exploration and production companies, Haskel specializes in air/gas driven systems used for the injection, dosing and metering of chemicals into oil and gas wells, pipelines, etc.

Chemical injection skid - dernuisifiers

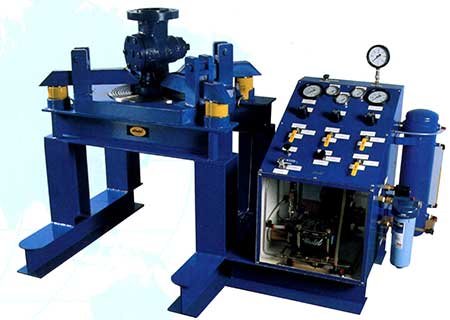

Haskel is a leading supplier of high pressure hydraulic systems to the fluid power industry. Whether it be systems for powering hydraulic jacks in aircraft ground support, clamping in the machine tool industry, hydraulic presses in the automotive and tire manu-facturing industry, or valve actuation in the energy market, Haskel systems can provide that total solution for these applications.

Valve actuator unit for geothermal plant

Chemical injection skid - corrosion inhibitor

Hydraulic power systems for aircraft jacks

For further information on Haskel products, visit our website at:

www.haskel.vnHaskel is an international organization offering a worldwide service through the Haskel group of companies and factory trained distributors. The Haskel group is headquartered in Burbank, California, with facilities throughout the world. We have built an enviable reputation for quality based on high pressure fluid and gas handling equipment.

In adcition to offering a comarehensive range of air driven liquid pumps, air amplifiers, air- and hydraulic-driven gas boosters, valves, fittings and accessories, we custom cesign and build power pacs and test rigs. This brochure introduces our General Product range. Technical details and advice on any of the products shown is available on request. Our continued investment in technology ensures that Haskel will stay at the leading edge of high pressure technology.

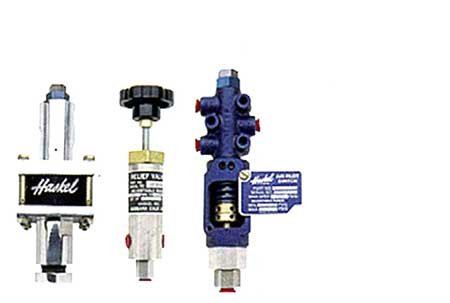

Haskel International otters a wide range of high pressure valves and system accessories designed to assist in the controlled use of pressure and flow-cenerating equipment manufactured by Haskel and others. Continuous investment in new machinery and technology keeps Haskel at the forefront of the field. Our selection of components includes:

Haskel manufactures BuTech high pressure industrial valves, subsea valves, ball valves, needle valves, check valves, fittings, filters, gauges, adapters and tubing. System components are available in every machinable alloy to handle pressures from vacuum to 150,000 psi (10,000 bar) and temperatures from -423°F (-253°C) to 1200°F (649°C).

BuTech subsea ball and needle valves are custom designed for instrumentation, process control, chemical injection and remote operated vehicle (ROV) use in the harshest environments, providing rugged protection, safety and reliability. Subsea ball and needle valves are used in template control panels, subsea well heads and Christmas trees.

BuTech standard and subsea valves are manufactured to mcet the requirements of NAGE MR0175/1S0 15156-2003, API6A and 17D, ASME, ANSI and various customer specifications.

BuTech Pressure Systems takes a proactive stance on the design, development and production of new and existing products to meet the most severe applications in harsh environments.

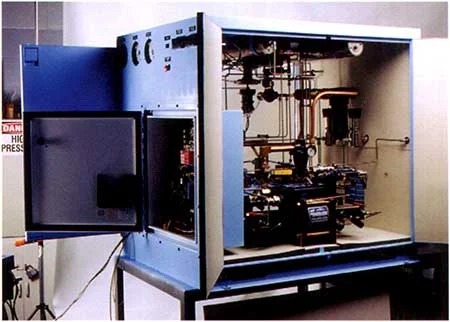

Haskel can custom-build portable-to-large PLC control systems for a wide range of industries and applications. Manufacturing divisions have clean room facilities for oxygen and similar requirements to class 1000-level clean.

CELEBRATING OVER 60 YEARS OF HYDRAULIC AND PNEUMATIC ENGINEERING EXPERIENCE IN THE DESIGN AND MANUFACTURING OF HIGH PRESSURE GENERATING EQUIPMENT AND CONTROLS

100 East Graham Place

Burbank, California 91502 USA

North Hylton Road

Sunderland SR5 3JD / England / UK

23 Tagore Lane #03-06

Tagore 23 Warehouse Complex

Singapore 787601

14 Parkview Drive

Archerfield, Queensland 41 08 Australia

Paseo Urbarburu 81 Edif.5 / 1 a Planta

Locales 1 y 2 Pol. 27 Martutene

20115 Astigarraga Gipuzkoa / Spain

Unit 14, Airways Industrial Estate, Pitmedden Road

Dyce, Aberdeen AB21 / Scotland

via Carabelli 28

21041 Albizzate / Varese / Italy

P.O. Box 7392

Abu Dhabi U.A.E.

www.haskel.vn